Digital Switching gets easier, cheaper, and more compelling

Until recently digital switching has only been seen on newly built, high-end boats. Now, Maretron and CZone both have digital switching products that can be retrofitted by a boat owner or pro installer and cost under $500. But, are these products easy to install and will the boat owner benefit from the installation? Read on to find out.

Digital switching is a complex topic and there are quite a few systems from several different manufacturers available today with more coming. This entry won’t be able to cover all the capabilities of the systems covered nor the specifics of installing each one. Over the coming year I plan to cover several of these systems in greater depth and show what’s involved in installing and configuring these systems to integrate them into your boat.

Benefits of digital switching

What’s a digital switch and why should I care? That’s a reasonable question and the answer is a little involved. When compared to traditional mechanical switches, digital switching’s biggest benefits are flexibility, reduced weight, weather sealed highly reliable switches, and automation. But, digital switching can also be a little harder to understand at first and troubleshooting can involve a computer instead of a multi-meter which can be intimidating.

Reduced weight through less wiring

Traditional DC switching and power distribution starts with a centralized electrical panel where very large cables are run from the batteries to the panel. Then, each circuit on the boat has a wiring run from the panel to the point of use. On my own boat that means that loads like the fresh water pump, located a few feet from the house batteries, run all the way from the batteries, to the panel, and then back down to the pump. So, power for a load that is three feet from the batteries travels through about 20 feet of wire. Wire is heavy and with the number of circuits on a modern boat that can add up to many hundreds or even thousands of pounds, much of which digital switching can help reduce.

Easy control from multiple locations

With traditional switching, wires must be run to each location you want a switch. On Have Another Day our salon lights can be turned on in two locations. So, there’s wire running to each switch plus another (traveller) running between the switches. This means that adding another switch can be a difficult and time consuming task that consumes lots of marine wire. With digital switching additional switches, or other controls like a touch screen or MFD, connect to the NMEA 2000 backbone of the boat; potentially dramatically simplifying installation.

Weather sealed

A traditional circuit has quite a few connections and each of these is a potential source of corrosion and trouble. Plus, mechanical switches have moving parts that are subject to failure. Digital switching circuits typically bring in a single source of power and then have a single connection to each load. There aren’t individual connections for circuit breakers, switches, and the load. Most digital switching modules are well sealed against the environment, utilize solid state switching, and offer a degree of reliability traditional mechanical switching simply can’t match.

Automation and configurability

Traditional mechanical switching can’t offer much in the way of automation, but digitally switched circuits open a world of possibilities. For example, with digital switching it’s possible to read the fresh water tank level from the NMEA 2000 network and turn off the fresh water pump if the level drops too low. Or, a circuit can be set to turn itself off after a specified delay. Plus, with more advanced digital switching systems the trip threshold can be set on a per circuit basis. So, if you have a load attached that should draw 8 amps you can set the trip threshold at 10 amps. But, if you replace that load with one that only draws 4 amps now you can easily change the trip threshold to 5 amps without making any other changes. Plus, systems with settable trip thresholds also have individual circuit current monitoring. Monitoring current consumption gives the ability to monitor and alarm if unusually high (short circuit) or low (burnt out bulb, freewheeling pump, etc) current is measured.

Cost comparison

When digital switching was first introduced to the marine market it commanded a substantial price premium over traditional mechanical switching, required certified installers, and was designed for installation as part of a new boat-build. But, as digital switching has matured, manufacturers have started offering less expensive and easier to configure versions of their products. Entry level digital switching products are available for as little as $250 for six circuits. I constructed a sample system with traditional mechanical switching for six circuits and it came to about about $200 but that doesn’t include any dimmers, which is built into most basic digital switching modules, nor does it account for a substantial difference in installation labor and supplies.

Hands on testing

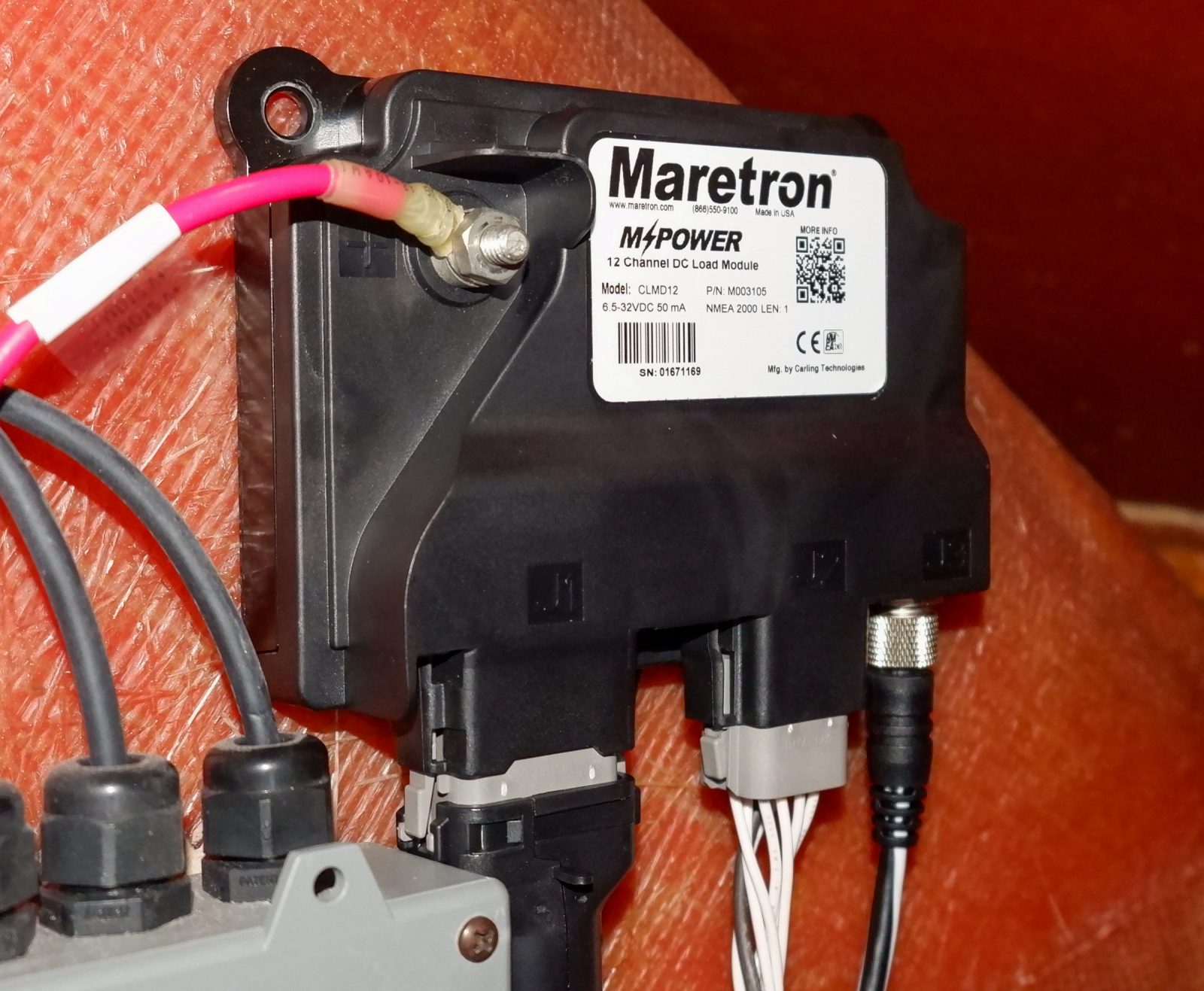

I’ve been testing digital switching products from Maretron and CZone. I have Maretron’s MPower CLMD12 12 circuit digital switching module along with their VMM6 6 button keypad and from CZone I have their Contact 6 Plus 6 circuit module along and their KP2x3 6 button keypad.

Maretron MPower

Maretron’s CLMD12 is a 12 circuit digital switching unit with settable trip thresholds, current monitoring, and dimming available on each of the 12 circuits. Additionally, the CLMD12 has 7 discrete inputs. Discrete inputs allow circuits on the CMD12 to be controlled by a mechanical switch or any other control equipment that can complete a circuit. Two of the twelve circuits handle a maximum of twelve amps, six are rated at ten amps, and four are rated at five amps. But, each of these circuits can be set to trip at lower current levels if a smaller circuit needs to be protected. Final pricing for the CLMD12 hasn’t been set, but Maretron expects it to carry a suggested list price of $495, making the per circuit cost pretty affordable at just over $41.

My CLMD12 switch module and VMM6 control unit came configured to work with each other out of the box without any configuration. But, if you want to take advantage of advanced features, Maretron’s line of switching is managed through their G2Analyzer software connected to the vessel’s NMEA 2000 bus by either a Maretron USB100 or IPG100. This software gives you control of an impressive number of parameters for configuring both digital switches and the keypad or rocker switch controls. G2 Analyzer allows the user to configure what happens in response to a button push on a control device, what lights should be lit on the switches, how many amps a circuit should trip at, dimming, default state at power-on, flashing lights and so many other parameters.

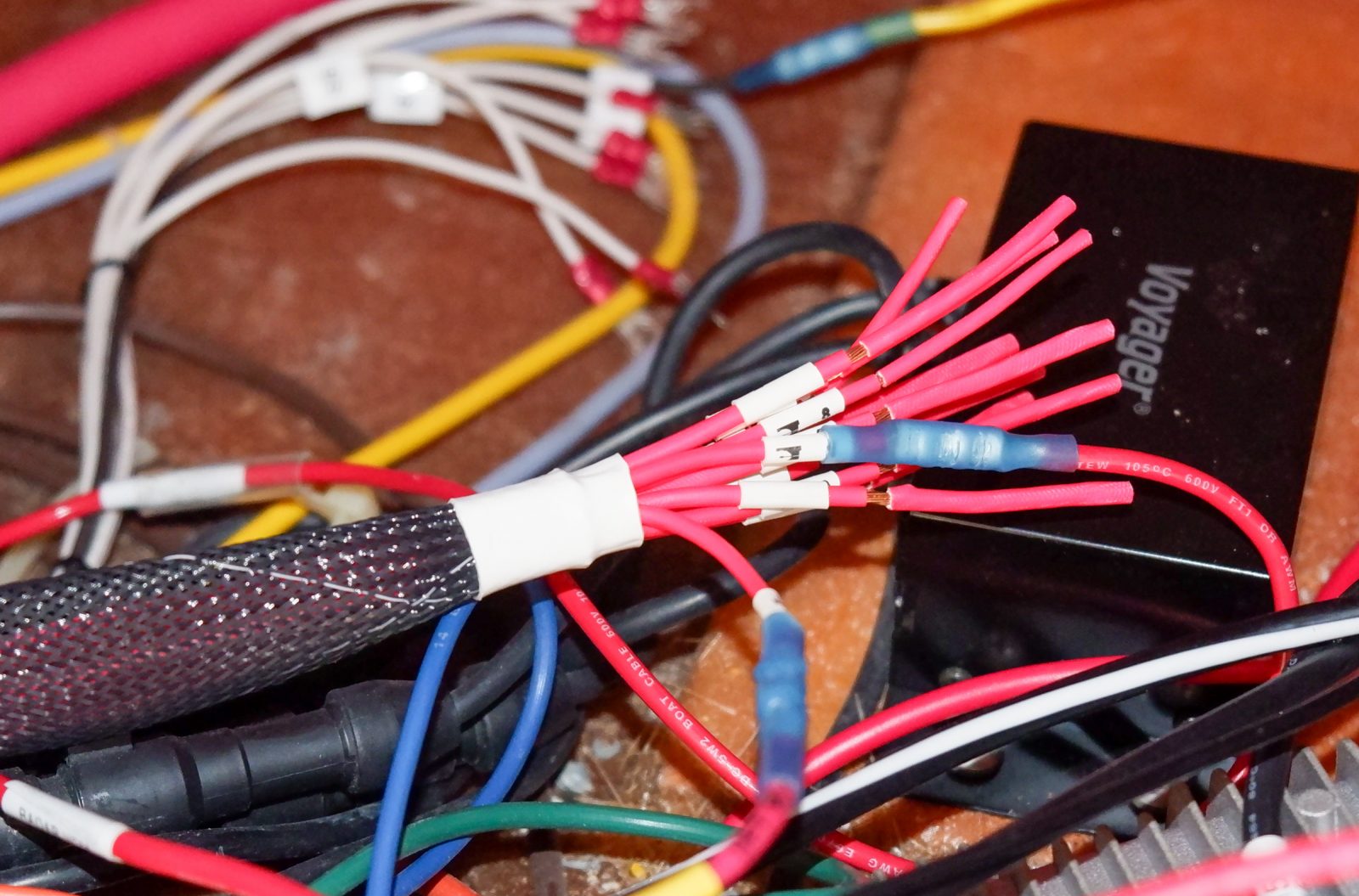

Installation

Physical installation of the CLMD12 is pretty straightforward. A single 10-32v volt positive input connects to the stud at the top left of the switch, a ground is supplied to the ground conductor, and a NMEA 2000 drop cable is connected to the DeviceNet port on the bottom right of the switch. Once these basic connections are made the loads and controls can be configured. With those loads configured the last step is to connect the actual loads to one of the 12 wires coming out of the bundle of wires connected to the Deutsch connector on the bottom left side of the unit (labeled J1). I got everything connected and a couple of circuits controlled within an hour or so, though I lost some time because I connected a 5 amp load to a circuit preset to a 3 amp trip threshold. Once I realized this and adjusted the trip threshold everything worked well and I had the opportunity to verify the trip thresholds work as designed.

Bypass module

In the event of a failed switch module, Maretron offers a bypass module for an estimated $195. The bypass module holds blade fuses for each of the 12 loads and also offers a mechanical on/off switch. Maretron’s intent is that a bypass module can be located next to each switch module or have one bypass handy for several switch modules. The bypass module comes with a short, 6 gauge, jumper to piggy back power off the switch module’s power supply. If the switch module fails, the 12-pin Deutsch connector, connected to J1 on the switch module, can be moved from the switch module to the receptacle on the bypass module.

Switches

Maretron’s primary switch module for aftermarket applications is the VMM6, a six actuator (fancy word for switch) module with replaceable keycaps to match any label need. The $130 VMM6 will be available with multiple actuator configurations, the sample above has, from left to right, five momentary single action rockers and one double action rocker. The double action rocker effectively has two switches and can be used, as shown, to brighten or dim a light, but can also be used to control two separate loads. The action taken with each switch press is configured in G2Analyzer and includes toggling a load on or off when pressed, one button dimmer control –which toggles the load when tapped and dims up and down when held–, flash the load off and on, just dim, just brighten, momentary (only on when the switch is held), and several other possibilities.

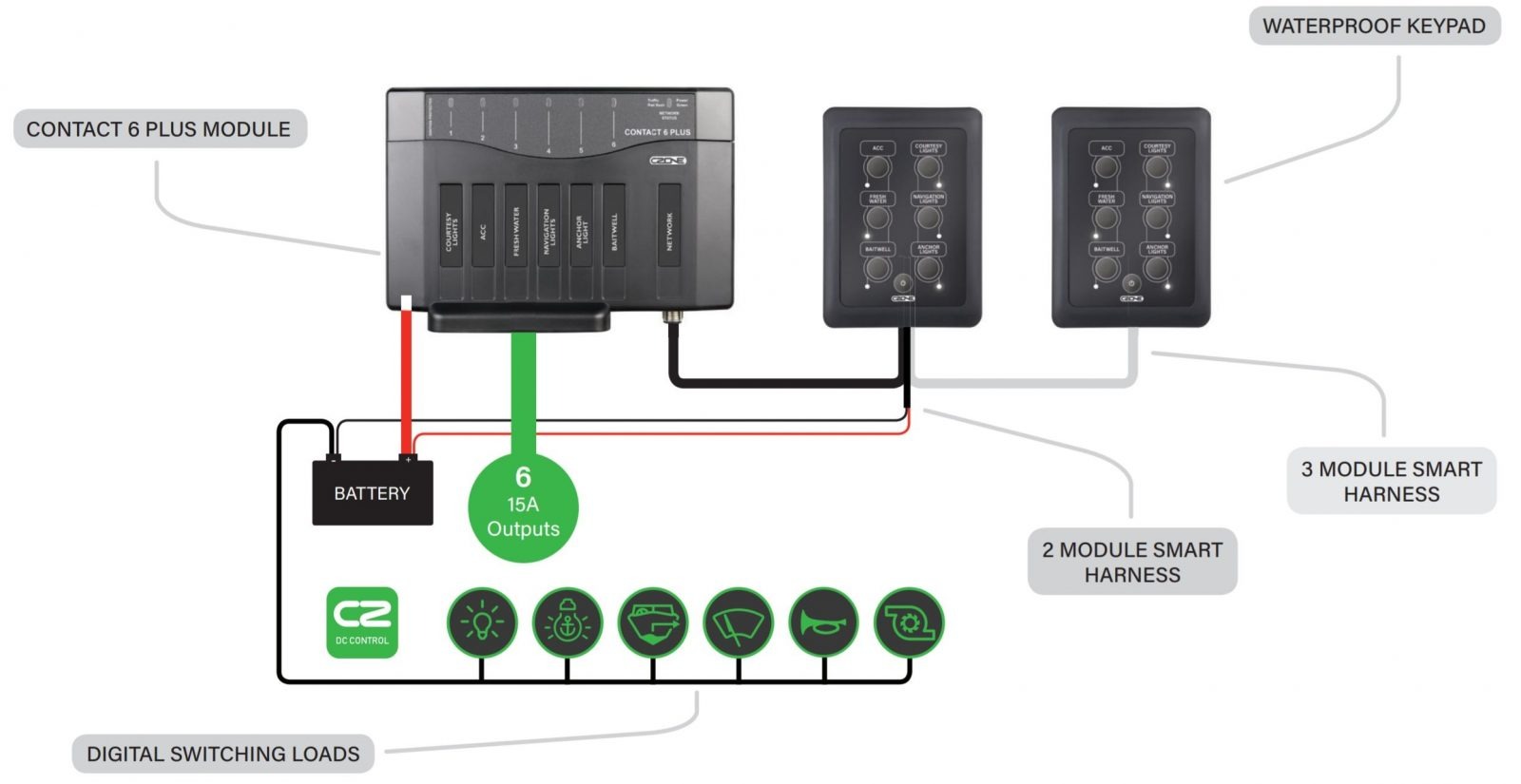

CZone Contact 6 Plus

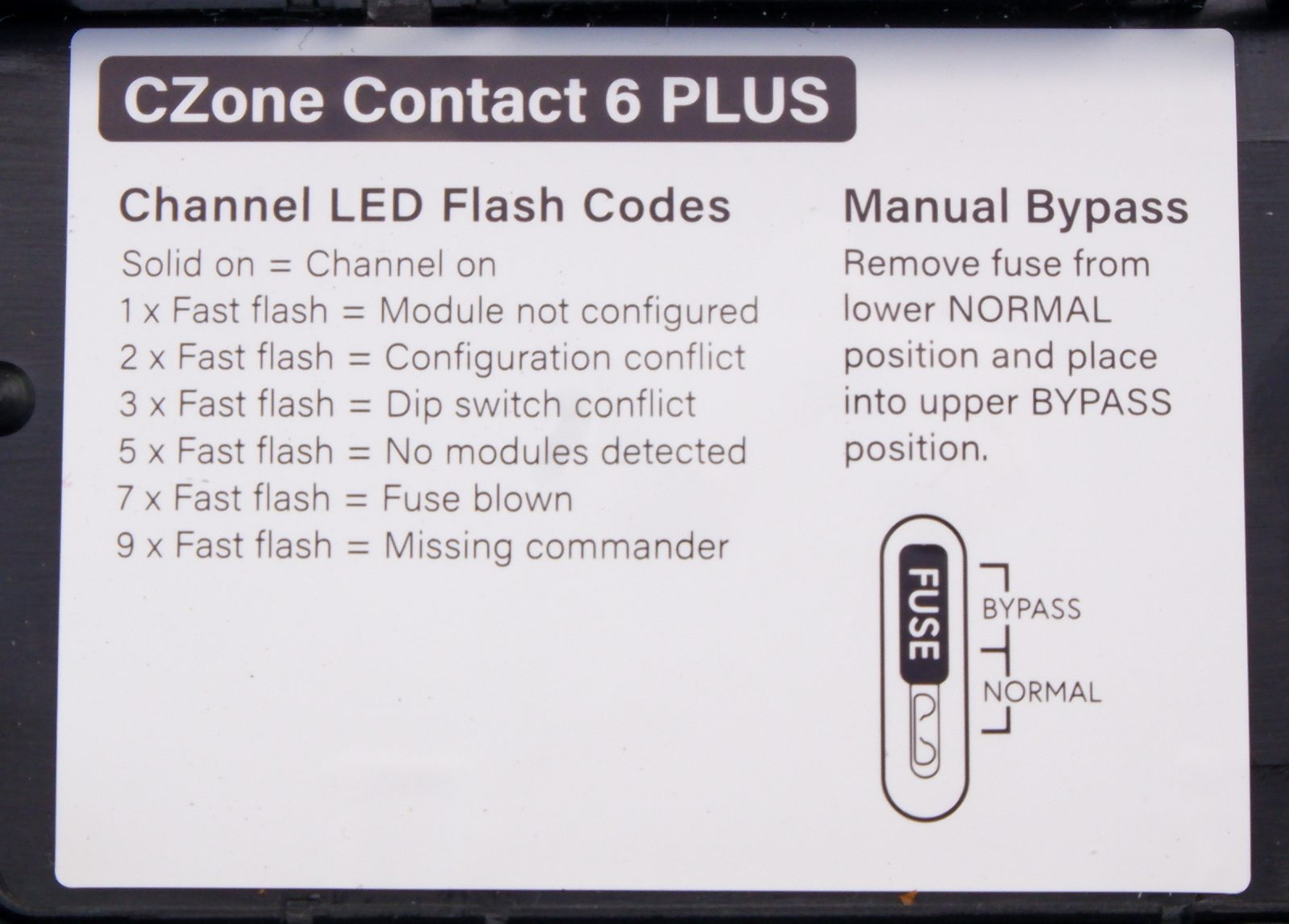

CZone’s Contact 6 Plus is a $250 6 circuit digital switching unit compatible with the full line of CZone digital switching and monitoring products. At about $42 per circuit the pricing is right in line with Maretron’s CLMD12 and also comparable to traditional mechanical switching. Each of the 6 circuits in the Contact 6 Plus can handle a maximum of 15 amps of 12 or 24 volt DC. The simpler Contact 6 Plus doesn’t have any of the discrete inputs or software configured trip thresholds of the Maretron switches. CZone has gone with a different circuit protection approach than Maretron or their own COI. The Contact 6 Plus uses physical ATC blade fuses for circuit protection and doesn’t have the ability to monitor current consumption. CZone’s use of physical fuses means you’ll need to keep spares on hand in case you blow one and also means access to the unit needs to be considered in order to replace fuses.

Contact 6 systems can be run as very small stand-alone switching systems with CZone’s Smart Harness. Smart Harnesses are available for two or three modules and are non-expandable NMEA 2000 networks. Out of the box Contact 6 systems come configured to run as a standalone system without other devices on their NMEA 2000 network.

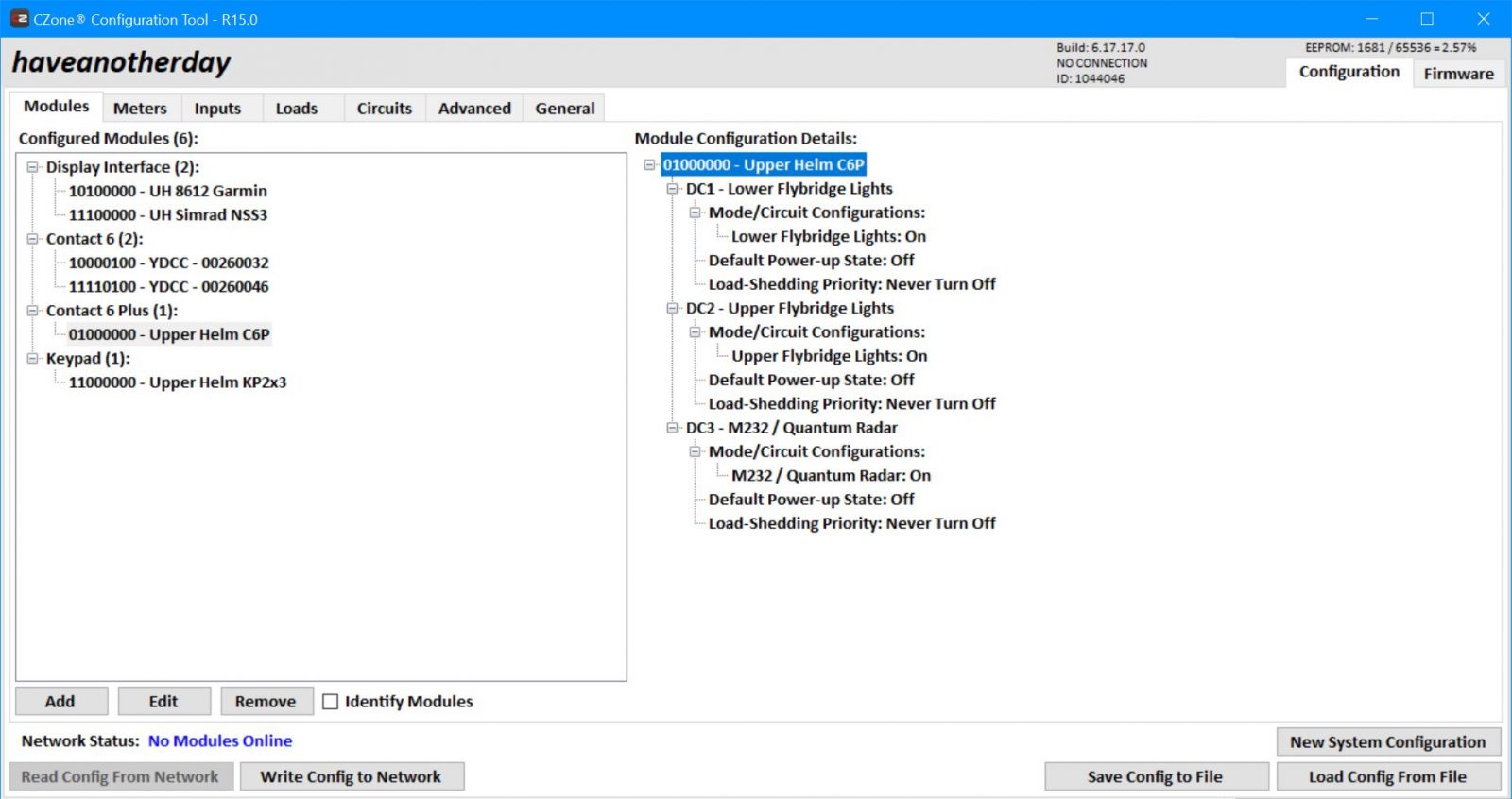

If you’re going to use your CZone system with other NMEA 2000 devices on the network you will need to build a configuration in the CZone Configuration Tool and upload it to the CZone components on the network. The configuration tool is very powerful and makes it easy to configure an advanced system. Once the system is configured you can save the configuration file to an SD card and use an MFD to load the configuration onto the network. This ability is really nice as it means no additional hardware is needed to configure your system if you already have a compatible MFD onboard.

Installation

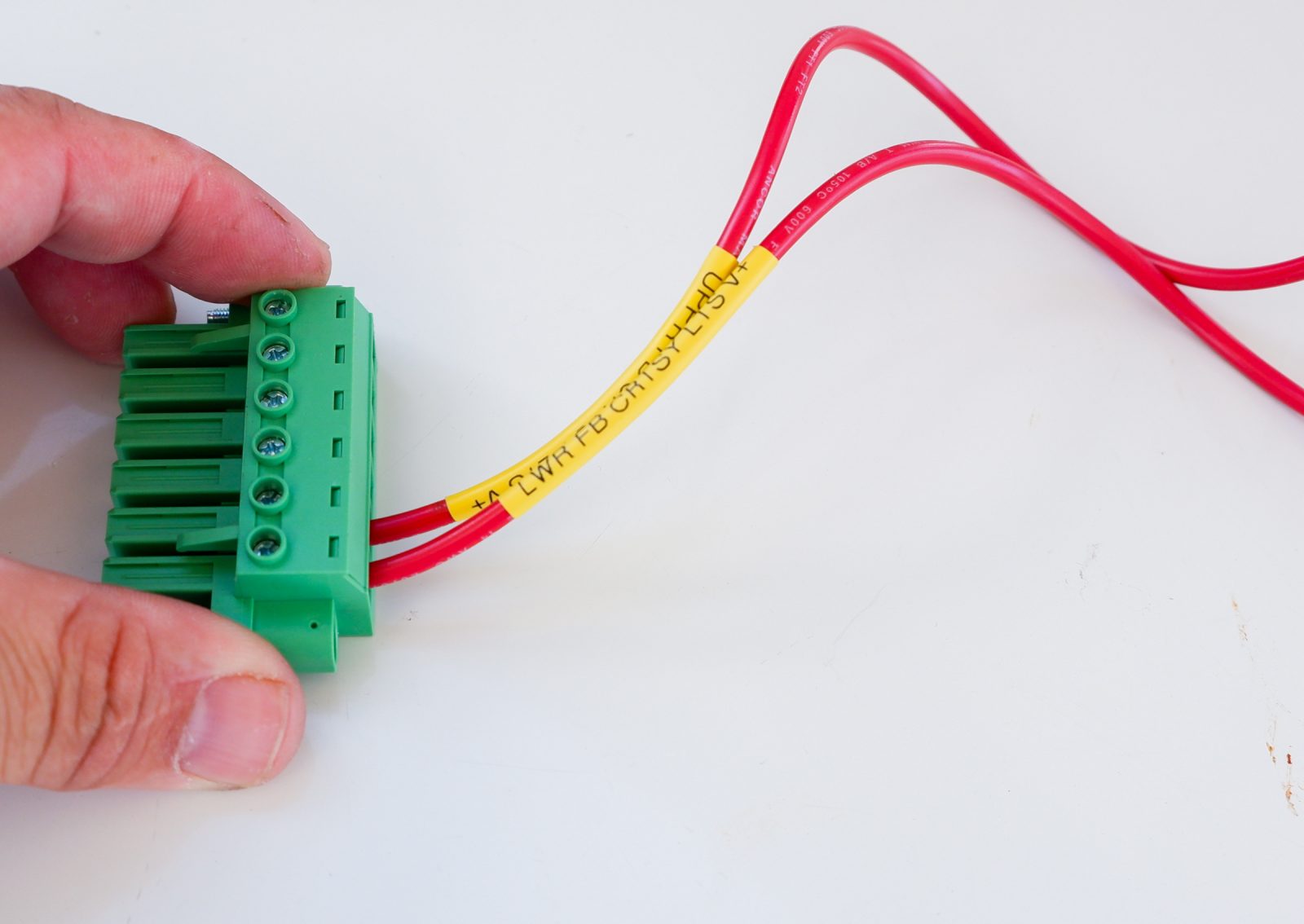

Installation of a Contact 6 Plus is also straightforward. The switch module accepts a single 12 or 24 volt DC positive input and a NMEA 2000 drop. The module draws ground through the NMEA 2000 connection. Loads are connected using a six pin plug-in screw terminal that accepts 8-24 gauge wires. Installation of the Contact 6 Plus took well under an hour but I had a bit more of a learning curve with the Configuration Tool so my time to successfully switching loads was similar to with the Maretron system.

Emergency bypass

CZone doesn’t use a separate bypass module, but instead there’s a secondary bypass position on each fuse holder. When the fuse is in the bypass position all digital switching circuitry is bypassed and a direct, fused connection is made between the power source and the load. There’s no additional expense for bypass functionality, but when compared to Maretron’s approach each circuit will need to be bypassed individually if the whole module fails.

Switches

CZone offers their keypad controls in six button ($220) and twelve button versions in both portrait and landscape orientations. When the Contact 6 Plus is operating in standalone mode with a smart harness, the push buttons can be configured to behave either as on/off toggle switches or as one button dimmers through a series of button presses. The labels on the panel are adhesive and the keypad comes with a sheet of 60 common labels. When the system is connected to a NMEA 2000 network and configured with the CZone Configuration Tool a much broader set of controls, like Maretron’s, are available.

Proprietary versus standard NMEA 2000 messaging

When manufacturers began designing their digital switching products the NMEA hadn’t added switching PGNs to the NMEA 2000 standard. As a result, manufacturers had little choice but to use proprietary messaging for their implementations. Since then the NMEA has modified the NMEA 2000 standard to include digital switching messages. Maretron has adopted those messages and operates on standard PGNs while CZone continues to use their proprietary messaging to control their switches. Within a single vendor’s system the use of standard or proprietary PGNs won’t change your experience with the products, but if you have multiple vendors’ equipment on the boat and hope to have it work together your options will be significantly better with NMEA 2000 standards compliant communications used.

Yacht Devices switching

So far we’ve talked about ambitious products with the potential to replace much of a boat’s DC distribution system. But, perhaps you’re looking for a simpler option to just control a few circuits. That’s where Yacht Devices‘ YDCC-04 circuit controller can come into play. First, a quick note that I own Yacht Devices U.S., the U.S. distributor of Yacht Devices’ parts. The YDCC is a 4 circuit switching device that takes a slightly different approach from Maretron and CZone.

The $250 YDCC is only an on/off device without dimming capabilities. Like Maretron it uses NMEA 2000 standard PGNs for all its control messages. It uses bi-stable relays to switch the circuits and these relays don’t have the ability to do PWM dimming. Additionally, the YDCC doesn’t take a single positive input and then distribute it, instead the switched leg is supplied for each circuit. The switched load can be AC or DC and nearly any voltage running up to 10 amps. The first two loads have outputs for when the circuit is on and off. This allows current to flow to one contact when the circuit is “off” and another when it’s on. There’s not any circuit protection in the YDCC so you’ll need it upstream of the module.

But, the YDCC also has a full set of contacts on the right side of the device for switching. On Have Another Day I’ve switched several loads in my cockpit using a YDCC and what you see above are the four switches connected to the YDCC to control those circuits and indicate their status.

Yacht Devices also offers the $150 YDSC-04 which doesn’t include any relays but allows you to view and control the status of a YDCC (or any other NMEA 2000 standard digital switch) via switches and indicator lights.

Final thoughts

Digital switching isn’t just for new boats. Digital switching brings lots of benefits to your boat. If you’re taking on a project today that requires new circuits it’s hard for me to see why you wouldn’t use one of the low cost, high featured digital switching options in the market. This isn’t to say there’s not a learning curve with digital switching, because there is, but I believe the benefits I talked about earlier easily outweigh the differences and potential complexities. Anytime I look at new systems or paradigms on a boat I try and answer one question… Will this make boating better, easier or more fun? With digital switching I believe the answer is it can make boating easier and better, giving you options you simply can’t have with traditional mechanical switching.

Ben, how do the products compare in power draw when our boats are in use vs unused? What choice are installers making when it comes to the bilge pump and bilge pump alarm? (Do installers connect them to these products, or leave them connected separately to the battery). If connected to the battery, do any of these products measure increase in bilge pump usage to increase awareness to the user there is a problem?

Dan,

I can’t find a spec for Maretron, but CZone says the standby current for the Contact 6 Plus is .3ma. Yacht Devices lists average current for the YDCC at 30ma. But, in all cases for these products to function the NMEA 2000 network needs to be powered up. I’d suspect that on most boats that represents a significantly larger load and concern than the consumption of the individual switching component.

On my own boat I haven’t run my bilge pumps through any of the digital switch products. My installations aren’t physically anywhere near the pumps and I don’t have enough operational data of my own to make that change yet. CZone and Maretron both offer products that can indicate when a circuit is energizied (frequently called a run-indicator) but I’d rather monitor bilge pumps with a stand-alone boat monitoring product that also has alerting capabilities integrated in.

-Ben S.

Some of the early systems I worked on (pre 2010) had the bilge systems tied into the digital switching, most of those switched to conventional bilge pump wiring by the boat builder after issues with battery draw and other system failures affecting the bilge system. I think the best solution maybe having the pump with separate power but monitored by both conventional and digital means.

That makes sense.

Im curious how the reliability is. Seems that is always the achilles heel of these systems. I really like the idea of it, but the real world application doesnt seem to jive. Fingers crossed

This has come a long way in 10 years since I last looked at it. Back then it was $400-$500 a circuit with 16 circuits and 2 controls pads.

I have been looking for this, and think it is a great idea. But it didn’t turn out like I thought it would. I had assumed there would be a doodad at the load/light that accepted power and the nmea2000 connection. Then you would control the device over the network. This would allow one run of power through the boat, and one run of the network cabling, with drops to the individual items. It seems counterproductive that each of these items still requires a separate power run to the load/light. I don’t see how a guy will save any complexity or runs of wire with this. It seems like the only reason to use this is for the MFD control of your load, which is fun and cool, but not terribly compelling.

In theory you place the modules near load groups so say one in the forward stateroom that controlled the lights in the stateroom and forward head, and maybe the bow lights and head vent fan. Instead of 5 pairs of wires running back to the main panel you would have a communication cable and a a pair of heavier gauge power cables, and each load would have a shorter run. This can be somewhat problematic finding places for the module that are accessible and make sense. The system has to be well engineered and thought out well in advance to really get good weight and wiring savings.

It’s possible car makers have to some degree done it. The real savings they found weren’t on the load side but the control side. SO say you have breaker panel feeding a switch panel with 8 switches on it then on to the loads. Wit digital switching you could now have a switch panel with only a communication cable and the loads can be fed directly from the circuit protection.

As some one who has spent the last decade and a half working with traditional circuit protection as well as digital switching I do take some exception to the reliability statement (at least in the marine world).

It may well be true in the future but not now.

We used to see the A series or world breakers last 20-30 years in typical recreational marine service, we typically started seeing module or digital switch failures in the 7-10 year range. You also had issues with support as the products age. Some systems have gone thru complete redesigns in the last 10 years and the old systems require rather expensive fixes thanks to that.

I still think it’s the future but I think potential adopters should keep in mind there are still some drawbacks that aren’t fully flushed out.

As an aside I also have done a little work with home automation systems. Very few home automation technicians have the systems in their house in my experience, The issue is when the systems age and are no longer supported it can get very costly versus buying a 5 buck light switch at home depot. Now current wireless systems have reduced that risk which I think is why you see so much more in that space now but remember the basic concepts have been doable for 40 plus years with little market penetration (x10)

It isn’t just weight savings. For some of the extra installation complexity, the owner also gets a boat simpler to operate. Rather than buttons programmed 1-1 to match the function of their circuit breaker counter-parts, the installer can have far fewer buttons. Much like you get in a car and have an on switch built into your ignition, you can have an “on” button for your boat that powers on the majority of breakers (instruments, electronics, vhf, etc.) then add buttons only for those devices out of reach of the user (nav lights)

This is very true and something the automtive and motorcycle space already does with multiple circuits tied together (mostly to the key switch but some others). Many multi plex systems do have these features, but one must be careful to make it intuitive. A certain boatbuilder tied many functions to 3 main ” macro buttons” that were supposed to relate to the boat being at dock at anchor etc. But it had the habit of confusing owners used to turning on everything individually. Used to get lots of service calls that were really more user error or interface misunderstanding then actual issues.

Another favorite My water heater won’t turn on! Yep it’s because your tank sensor is bad and it has a default to kill power to the water heater when the tank is empty.

I miss Naviop

something else to mull over https://www.neutrinoblackbox.com/products

The motorcycle industry has developed some intriguing modules. The Moto brain and PDM 60 are another 2 I have come across.

Another option for fun, non-critical digital switching. Wire a $35 Google nest mini direct to your 12v. Add a $13 12v 5amp 2 circuit wifi digital switch : https://www.amazon.com/gp/product/B07PGPRZ51/ref=ppx_yo_dt_b_asin_title_o08_s02?ie=UTF8&psc=1 in parallel at your switch panel ( I wired to courtesy lights). Configure the apps and then you can switch your lights at the panel, or on your phone, or by voice “Hey Google switch courtesy lights on” . Under $50 and a half hour. Obviously not appropriate for critical loads. But nice for lights, Music, etc.

Very interesting technology. If digital switching modules were the exact size of standard boat circuit breakers it would be a no brainer to upgrade existing boats. Like home based z-wave digital switching you would then have a mechanical backup.

Maybe somwonw can help me out here How and where can i purchase the MPower modules ?

Unfortunately to the best of my knowledge these modules aren’t available for purchase yet. I’m going to submit a question to the folks at Maretron and see if there’s an update.

Best,

Ben

I’ve just checked in with Maretron who confirms they’re finalizing pricing and availability and will update as soon as the products are available.

-Ben S.

Thanks Ben I will be patient but have my order ready as soon as the products are available

This is great, and finding someone who has got the pieces working. I’ve tried (unsuccessfully) to hook up a Maretron DCR100 to a Garmin 922. The Garmin’s latest software shows switching ui (cool!), and shows switch status changes when a Maretron 150 is used to flip switches, but the 922 won’t control the Maretron directly.

Mr. Stein, Thank you for sharing all this knowledge. I’ve been trying to connect a Maretron DCR100 to a Garmin 922xs MFD, with “limited” luck. Latest Garmin software on 922 shows the DCR, shows the status of the DCR switches (when I flip them with a Maretron controller), but won’t actually flip a switch.

It would appear to be one of two things: 1) need a CZONE config (black magic? supported by Maretron?), or 2) the Garmin is sending the 127502 message, which Maretron stopped supporting a version ago. Neither of the two companies seem to have a great idea here, other than “monitor and see what’s going on” … the monitoring gear would cost more than the switch gear!

All suggestions welcome!

So how do folks handle higher amp devices with digital switches (pumps, downriggers, radars, etc)? Do folks just leave standard mechanical switches for those devices (which would seem to defeat the point of having a digital switching system on their boat in the first place)? I’ve been researching digital switching systems as a potential for my boat rewiring project but the lack of higher amp support is one question I just don’t seem to see addressed anywhere.

Todd, I’m pretty sure that most digital distribution systems let you parallel output channels to get the maximum amperage needed for a particular circuit. For instance, the newish CZone Control X Plus has 24 DC output channels with just four being 15 amps max, the rest less. But with paralleling it can support a circuit that needs up to 80 amps.

Details in the install manual: https://www.czone.net/en/p/80-911-0230-00/Control-X-PLUS-w-Connects

Ben is exactly right about the potential for higher current being satisfied by using multiple channels. I’d think that would deal with most typical loads, but not things like windlasses, etc. For really high current applications, the digital switches can be used to control relays or solenoids.

-Ben S.

Thanks @BenEllison and @BenStein – helpful – I love the idea of reducing wiring through my boat thru the use of strategically placed PDM’s but for the life of me was stumped on the higher amp management.